Lightning Bolts

Lightning Bolts are developed to replace threaded fasteners in applications where quick installation and removal times are required. They also offer several other advantages such as no alignment or threading issues since ZipNut ® collapsible thread technology is utilized. Threaded segments are collapsed in the installer’s hand by simply squeezing the bolt in your hand (double-action of pulling and pressing against the palm of your hand). This will allow the bolt to be installed or removed quickly. Once the threaded segments are fully extended, they are locked into place and the bolt can be tightened or loosened as desired.

Our shield door design is constructed of lightweight materials such as aluminum and polycarbonate. The shielding is Radium’s ClearView Radiation Shielding which is 40% lighter than lead in equivalent radiation attenuation and is environmentally friendly and non-toxic. The ClearView RS™ solution is transparent and transforms the traditional solid metal door into a viewport on the manway. Platform technicians can now view into the channel head and view robotic operations with the door in the closed position. This transparency will reduce the amount of times the door needs to be opened and makes the platform technician a more efficient worker.

HEPA hose has been moved off of the front of the door and integrated into the door mount. When used on a Westinghouse steam generator, the hot and cold leg shield doors have a HEPA hose section that is connected to the shield door HEPA “Y” selector. The HEPA hose never needs to be moved and essentially makes this a one time per outage installation and removal door.

Steam Generator Primary Manway Insert Inspection Cart

Radium designed a lightweight compact cart that stores the inserts when they are removed from the primary manway. Each cart is designed to hold 2 inserts in their designated (hot or cold leg) slots on the cart. The inserts are supported on polyethylene rollers that allow rotation of the inserts for cleaning and inspection processes. The insert do not come into contact with metal. The rollers fully support the inserts even with the lid installed.

The compact cart is designed to streamline the cleaning, inspection, and storage of the inserts on the primary platform. This is a safer way to accomplish these tasks and can be done using the ALARA principles to ensure dose is minimized.

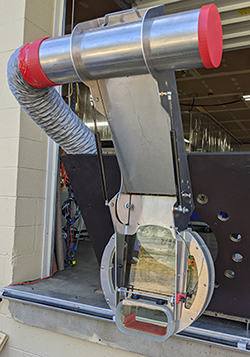

Steam Generator Primary Manway Cover Elevator System

Radium developed a Primary Manway Cover Elevator System that can safely and efficiently removal and install your covers.

The system consists of two worm gear winches that are capable of lifting 1200 lbs. each which gives you a total lift capacity of 2400 lbs. for each cover. The winches are powered by 110 VAC electric motor. Each are operated through a momentary push button pendant used by the technician on the platform.

Steam Generator Primary Manway Cover Centering and Locating System

The Steam Generator Primary Manway Cover Centering and Locating System is designed to take the manway cover from a vertical position to the manway opening effortlessly.

With the weight of the cover supported by chain hoists or other means, the system’s set of strap winches pull the cover to the manway opening and align it with the bolt-hole pattern. Manway studs are installed and the system is removed.

Steam Generator Leak Detection System

In rare occurrences, steam generators nozzle dams can leak after they are installed which creates issues with eddy current operations and the health physics department for containing the water. Radium has developed a mobile leak detection system which can be staged in the containment building and deployed quickly to remove the water from inside the steam generator primary channel head. The system can be deployed as a preventive measure or in an as-needed basis.

Conventional fluorescent tube stick lights are fragile by design and typically break even during light industrial use. This creates many issues such as disposing of hazardous material (fluorescent tubes contain mercury which requires special disposal process), loss of work time to get a replacement light, and creates an unsafe work area due to sudden loss of light. Our patented (# 9,310,067) LED Stick Lights solve all of those problems. They also provide more than twice the amount of light, waterproof to 100 feet deep, can operate over 5 years non-stop, all in a compact impact resistant polycarbonate housing. They can be purchase online at LEDStickLights.com