Steam Generator Primary Manway Shield Door

with ClearView Radiation Shielding

Steam generator primary side maintenance activities comprise of many work environment challenges once the manway covers have been removed. Keeping the high contamination levels and the very high dose rates inside the steam generator channel head while various work activities are supported at the manway is one of the biggest.

Traditional shield door design has not changed for decades. These doors are constructed of heavy metals (and in lead’s case, toxic) and are very awkward to install, use, and remove. This awkwardness has contributed to the spread of contamination, additional exposure, unauthorized access, and injuries as history has taught us.

The Radium Steam Generator Primary Manway Shield Door is an innovative solution to all of the traditional shield door problems.

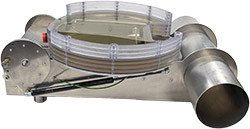

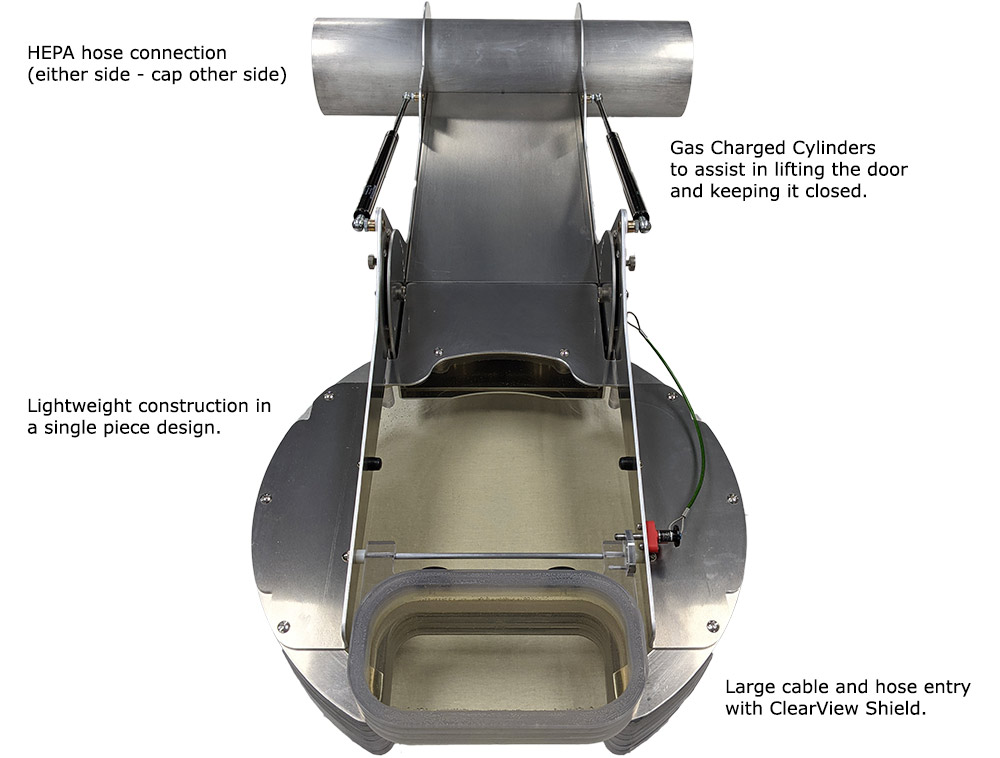

Our patented shield door design is constructed of lightweight materials such as aluminum and polycarbonate. The shielding is Radium’s ClearView RS solution which is 40% lighter than lead in equivalent radiation attenuation and is environmentally friendly and non-toxic. The ClearView RS® solution is transparent and transforms the traditional solid metal door into a viewport on the manway. Platform technicians can view into the channel head and view robotic operations with the door in the closed position. This transparency will reduce the amount of times the door needs to be opened and makes the platform technician a more efficient worker.

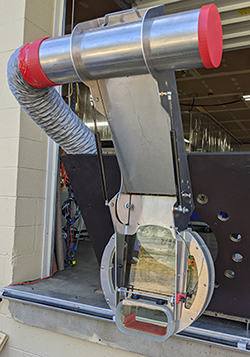

The HEPA hose connection on traditional doors is mounted on the front of the shield door. There is a long history of problems with this configuration. From hoses falling off the doors, to taking up valuable platform space, and having to be moved every time a door needs to be opened, there always seems to be issues with them during every outage. Radium has solved these issues by relocating the HEPA hose off the shield door and away from the manway as shown above on a Westinghouse Steam Generator.